NOM-012-CONAGUA-2021 and US/Canadian Plumbing Standards

Why Compare Plumbing Standards?

The faucet industry has evolved rapidly across North America, with growing attention to water safety, durability, and environmental responsibility. While the United States and Canada have long relied on standards such as NSF/ANSI 61 and CSA B125.1, Mexico introduced NOM-012-CONAGUA-2021, a modernized regulation aimed at protecting consumers and improving the quality of plumbing products.

For faucet manufacturers and importers, understanding the differences and similarities between NOM-012-CONAGUA-2021 and U.S./Canadian plumbing standards is more than a technical matter—it is a crucial step toward successful market access. Compliance ensures that products meet regional safety requirements, qualify for government tenders, and build consumer confidence.

As global supply chains integrate, many faucet brands operate in multiple regions, requiring them to meet standards across borders. Comparing faucet standards Mexico, plumbing standards USA, and plumbing standards Canada helps clarify testing expectations, documentation, and performance metrics.

By understanding these frameworks, companies can avoid delays, reduce certification costs, and align their production to international expectations for lead-free faucets, water efficiency, and product reliability.

Overview of NOM-012-CONAGUA-2021 (Mexico)

The NOM-012-CONAGUA-2021 standard represents a significant modernization of Mexico’s plumbing regulations. Published by CONAGUA (National Water Commission of Mexico), it specifies the requirements that faucets, valves, and accessories for potable-water hydraulic installations must meet before being sold or imported into Mexico.

The primary purpose of NOM-012-CONAGUA-2021 is to ensure that all plumbing fixtures are safe for human consumption, resistant to corrosion, and environmentally efficient. In simpler terms, it guarantees that faucets installed in Mexican homes and buildings deliver clean, uncontaminated water while maintaining durability and minimizing waste.

Scope and Application

NOM-012-CONAGUA-2021 applies to:

- Faucets and valves for potable water installations in residential, commercial, and industrial applications.

- Mixing faucets, shower valves, and accessories that come into contact with drinking water.

- Imported faucets that must demonstrate equivalent compliance before entering the Mexican market.

For manufacturers, compliance with NOM-012-CONAGUA-2021 is mandatory for legal sale or distribution in Mexico. The standard requires testing and certification through CONAGUA-approved laboratories, ensuring that the product meets the technical specifications outlined in the regulation.

Understanding NOM-012-CONAGUA-2021: Why Mexico’s Faucet Standard is Crucial for Manufacturers and Consumers

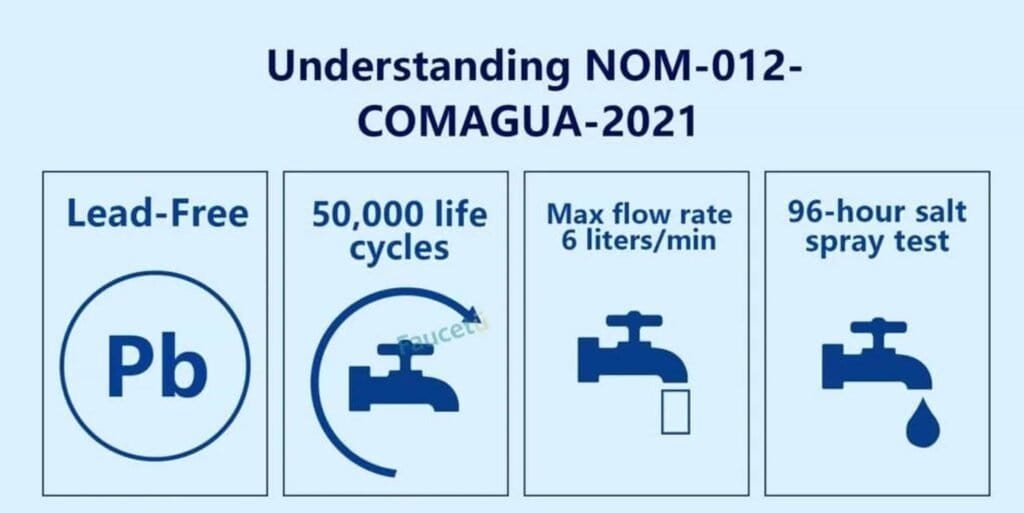

Key Technical Requirements

- Lead-Free Material Limitation

NOM-012-CONAGUA-2021 strictly limits lead content in components that contact drinking water. The standard aligns with international expectations, capping total lead concentration at 0.25%. This requirement ensures faucets are classified as lead-free faucets, protecting consumers from potential heavy-metal exposure. - Corrosion Resistance – 96-Hour Salt Spray Test

To evaluate the long-term resistance of faucet surfaces, NOM-012 requires a 96-hour salt spray test. This accelerated corrosion test exposes the product to a controlled saline environment, simulating years of use in humid or coastal areas. Faucets that pass this test are proven to have superior plating adhesion and protective coating quality. - Mechanical Durability Testing

The standard includes operational testing to verify the strength and longevity of moving components such as handles and cartridges. Faucets must withstand thousands of cycles of opening and closing without leakage or performance loss. - Flow Rate Control

NOM-012 sets maximum flow limits to promote water efficiency standardsin Mexico. Typical kitchen faucets are limited to 9 liters per minute, aligning closely with EPA WaterSenserequirements in the U.S. This ensures consistent conservation across markets. - Product Marking and Identification

Each compliant faucet must display the NOM-012-CONAGUA-2021 marking, along with the manufacturer’s name or trademark and the certification body’s logo. This marking helps consumers and inspectors verify compliance quickly during audits or inspections.

Testing and Certification Process

Obtaining NOM-012-CONAGUA-2021 certification involves several key steps:

- Sample Submission:The manufacturer provides product samples to an accredited Mexican laboratory authorized by CONAGUA.

- Laboratory Testing:Tests are performed for lead content, salt spray resistance, flow rate, and mechanical durability.

- Evaluation of Technical Documentation:The applicant must submit drawings, material composition, and performance data.

- Issuance of Certificate of Compliance:Once all tests are passed, the lab issues a certificate that allows the product to bear the NOM-012-CONAGUA-2021 mark.

- Ongoing Surveillance:Certified products are subject to periodic verification to maintain compliance.

This process ensures that all faucets sold in Mexico meet the same high-quality benchmark, safeguarding public health and enhancing the credibility of certified brands.

Importance for International Manufacturers

For global faucet producers—particularly those based in China, Europe, or the United States—obtaining NOM-012-CONAGUA-2021 compliance opens the door to Mexico’s fast-growing construction and renovation market.

Manufacturers who already meet NSF/ANSI or CSA requirements will find partial overlap with NOM-012-CONAGUA-2021, especially regarding lead content and flow performance. However, the salt spray test and certain labeling requirements are unique to Mexico and must be verified separately.

Firms like Faucetu, which specialize in OEM faucet production, often integrate these requirements directly into the manufacturing process. By ensuring material compliance, plating quality, and hydraulic performance, they can seamlessly supply to both North American and Latin American markets.

Key Takeaways

Mandatory for all faucets sold in Mexico.

Focuses on lead-free, corrosion-resistant, and water-efficient products.

Certification must be obtained through CONAGUA-approved labs.

Helps build trust with Mexican importers and end consumers.

Overview of US Plumbing Standards

When discussing plumbing standards USA, the regulatory framework is built on decades of public health protection and water conservation initiatives. The United States uses a combination of federal regulations, voluntary certifications, and industry standards developed by technical organizations such as NSF International, ASME (American Society of Mechanical Engineers), and the EPA (Environmental Protection Agency).

For faucet manufacturers and distributors, compliance with these faucet standards USA is essential for product acceptance by building inspectors, retailers, and end consumers.

Core US Standards for Faucets

1. NSF/ANSI 61 – Drinking Water System Components

The NSF/ANSI 61 standard is the most recognized faucet standard in the United States. It ensures that materials and components in contact with drinking water do not leach harmful contaminants.

This includes testing for lead, arsenic, and other heavy metals, guaranteeing that lead-free faucets are safe for human use.

Manufacturers must submit samples for chemical extraction testing, where water is circulated through the faucet for a specific duration. Any leached contaminants must remain below the defined limits.

This certification is mandatory in most U.S. states for any faucet that will be connected to potable water systems.

2. NSF/ANSI 372 – Lead-Free Verification

While NSF/ANSI 61 covers a wide range of chemical contaminants, NSF/ANSI 372 focuses specifically on lead content.

To be labeled as “lead-free,” the faucet’s wetted surfaces must contain no more than 0.25% lead, the same requirement enforced by NOM-012-CONAGUA-2021.

Faucets meeting NSF/ANSI 372 often display the “NSF LEAD-FREE” or “NSF-61/372” marking, helping consumers identify safe products.

3. ASME A112.18.1 / CSA B125.1 – Performance and Mechanical Testing

The ASME A112.18.1 / CSA B125.1 standard governs mechanical performance, including:

- Pressure and temperature resistance.

- Flow rate and spray pattern control.

- Handle torque and structural strength.

- Durability of valves and moving parts.

This joint U.S.-Canadian standard ensures that faucets perform reliably under typical household water pressure (usually up to 1 MPa).

4. EPA WaterSense – Water Efficiency Program

The EPA WaterSense program promotes water efficiency standards by certifying faucets that use 20% less water than standard models without sacrificing performance.

To qualify for the WaterSense label, a bathroom faucet must not exceed a flow rate of 1.5 gallons per minute (5.7 L/min), while kitchen faucets must not exceed 2.2 gallons per minute (8.3 L/min).

This aligns closely with Mexico’s NOM-012-CONAGUA-2021 flow limit, reflecting North America’s unified commitment to water conservation.

Certification Bodies and Process

US certification is carried out by accredited laboratories such as IAPMO R&T, UL, CSA, and NSF International.

The process typically includes:

- Material testingfor lead and other contaminants.

- Mechanical performance testsunder ASME/CSA standards.

- Factory auditsto ensure quality consistency.

- License issuanceto apply NSF, CSA, or WaterSense logos.

Most certifications must be renewed annually, maintaining continuous product compliance.

Importance for Exporters and Manufacturers

For international manufacturers—especially those exporting from China or Europe—achieving NSF or ASME certification greatly enhances credibility.

Products bearing the NSF or WaterSense mark are trusted by American consumers and building professionals alike.

Moreover, many large retail chains such as Home Depot, Lowe’s, and Ferguson require proof of compliance before listing any plumbing product.

For companies already meeting NOM-012-CONAGUA-2021, achieving NSF/ASME certification involves only minor additional testing, since the lead-free and flow rate requirements are largely consistent.

Overview of Canadian Plumbing Standards

Canada’s plumbing regulations are highly aligned with those in the United States but include additional requirements to ensure bilingual labeling, regional enforcement, and public safety oversight.

The Canadian Standards Association (CSA) plays a leading role in setting and maintaining the country’s plumbing product standards.

For manufacturers exporting to Canada, compliance with plumbing standards Canada ensures legal market access and consumer confidence.

Key Canadian Faucet Standards

1. CSA B125.1 – Plumbing Supply Fittings

CSA B125.1 is the foundational faucet performance standard in Canada, harmonized with ASME A112.18.1. It defines mechanical, structural, and performance requirements, ensuring that faucets are leak-free, durable, and safe under standard water pressure.

The tests evaluate:

- Handle torque and strength.

- Spout rotation and durability.

- Thermal shock resistance (for hot/cold mixing valves).

- Corrosion resistance through cyclic exposure.

This is the most widely recognized plumbing standard in Canada for both residential and commercial fixtures.

2. CSA B125.3 – Plumbing Fittings with Backflow Protection

This standard focuses on anti-siphon and backflow prevention, ensuring that faucets and valves do not allow contaminated water to flow back into the potable system.

It is particularly relevant for kitchen sprayers and shower valves with built-in check valves.

While NOM-012-CONAGUA-2021 includes general flow and safety requirements, CSA B125.3 adds a more specific public health safeguard that complements Mexico’s corrosion and durability focus.

3. NSF/ANSI 372 – Lead-Free Requirements

As in the U.S., Canada enforces the NSF/ANSI 372 lead-free standard, ensuring that the faucet’s wetted surfaces contain no more than 0.25% lead.

This aligns directly with NOM-012-CONAGUA-2021 and demonstrates shared commitment to lead-free faucets across North America.

Marking and Labeling Requirements

One unique aspect of Canadian faucet compliance is bilingual labeling. All packaging and documentation must appear in both English and French, reflecting the country’s federal language laws.

The product must also display the CSA mark, confirming independent certification.

If the faucet also meets NSF or WaterSense criteria, those logos may appear alongside the CSA mark.

Certification Process in Canada

The certification process mirrors that of the United States:

- Submit product documentation and samples to a CSA-accredited testing laboratory.

- Complete lead, flow, and mechanical performance tests.

- Undergo factory inspectionto verify production control.

- Receive authorization to apply the CSA certification mark.

Canada’s enforcement agencies actively monitor plumbing product imports. Non-compliant faucets can be denied entry or recalled, underscoring the importance of full certification.

Key Differences Between Canada and Mexico

Aspect | NOM-012-CONAGUA-2021 (Mexico) | CSA Standards (Canada) |

Certification Authority | CONAGUA-approved labs | CSA Group or IAPMO Canada |

Language Requirement | Spanish documentation | English & French bilingual |

Flow Rate Limit | 9 L/min typical | 8.3 L/min (WaterSense alignment) |

Salt Spray Test | Mandatory (96 hours) | Optional corrosion testing |

Marking | NOM-012 label | CSA, NSF, or WaterSense logos |

Although both standards ensure safe, efficient, and lead-free products, NOM-012-CONAGUA-2021 places greater emphasis on salt spray corrosion resistance and plating durability, while CSA standards emphasize mechanical performance and bilingual compliance.

Importance for Cross-Border Manufacturers

Manufacturers that export faucets to both Mexico and Canada can significantly reduce testing redundancy by aligning internal quality controls with shared parameters such as:

- Lead-free compliance (≤0.25%)

- Flow-rate control (≈8–9 L/min)

- Mechanical endurance and leak resistance

By incorporating these requirements from the design stage, OEM suppliers like Faucetu can deliver multi-market compliant products, appealing to distributors across all North American countries.

Key Similarities Across the Three Standards

Despite differences in administrative structure and testing procedures, NOM-012-CONAGUA-2021, U.S. plumbing standards, and Canadian plumbing standards share one common mission — to ensure that faucets deliver safe, durable, and environmentally responsible performance.

These standards are built on similar engineering principles, with aligned limits for lead content, flow control, and mechanical endurance. Manufacturers who comply with one system often find it easier to adapt to the others with minimal design changes.

Shared Commitment to Lead-Free Faucets

Across Mexico, the U.S., and Canada, the lead-free faucet requirement has become a universal expectation.

Each standard—whether NOM-012-CONAGUA-2021, NSF/ANSI 372, or CSA B125.1—restricts the maximum lead content in wetted materials to 0.25% by weight.

This alignment reflects a regional consensus on protecting consumers from toxic exposure and supports international trade in compliant plumbing products.

Lead-free compliance has also become a key marketing point for faucet brands targeting eco-conscious buyers and government projects.

Mechanical Performance and Durability

All three standards require mechanical endurance testing to ensure faucets can withstand years of daily operation.

In NOM-012-CONAGUA-2021, faucets must complete opening and closing cycles without leakage or component failure.

Similarly, ASME A112.18.1 / CSA B125.1 subjects faucets to mechanical torque, vibration, and pressure resistance tests.

The shared goal is to confirm that handles, cartridges, and internal valves can operate reliably under normal domestic water pressure for a lifetime exceeding 500,000 cycles.

Flow Rate and Water Efficiency Standards

Water conservation is a growing global concern.

The EPA WaterSense, CSA B125, and NOM-012-CONAGUA-2021 standards all specify maximum flow limits to reduce water waste while maintaining user comfort.

Faucet Type | NOM-012-CONAGUA-2021 | U.S. (WaterSense) | Canada (CSA/WaterSense) |

Bathroom Faucet | ≤ 5.7 L/min | ≤ 5.7 L/min | ≤ 5.7 L/min |

Kitchen Faucet | ≤ 9 L/min | ≤ 8.3 L/min | ≤ 8.3 L/min |

Shower Valve | ≤ 9.5 L/min | ≤ 9.5 L/min | ≤ 9.5 L/min |

This near-identical flow performance across borders means that one faucet design can be easily certified in multiple regions with minor adjustments.

Surface Quality and Corrosion Resistance

While Mexico’s NOM-012-CONAGUA-2021 emphasizes a 96-hour salt spray test, the U.S. and Canadian standards also value corrosion resistance, even if the exact test method differs.

Faucets must show no peeling, blistering, or discoloration after exposure to humid or salt-laden environments.

This shared requirement ensures consistent quality for metal-plated finishes such as chrome, brushed nickel, and gunmetal, which are popular across all markets.

Health and Environmental Protection

Each of the three standards integrates environmental responsibility into its framework.

- Lead-free complianceprotects human health.

- Flow controlensures water efficiency.

- Material restrictionsprevent the use of hazardous alloys or coatings.

This convergence shows a collective effort by North American regulators to promote sustainable manufacturing and protect end users.

Testing and Certification Transparency

Transparency is another shared value. All certification systems—CONAGUA, NSF, and CSA—require detailed documentation, sample testing, and ongoing surveillance audits.

This consistency gives importers and consumers confidence that certified faucets truly meet safety and performance expectations.

For OEM manufacturers, maintaining complete traceability of materials and test results is now standard practice in global trade.

Major Differences: NOM-012 vs US/Canadian Standards

While the NOM-012-CONAGUA-2021 regulation aligns broadly with U.S. and Canadian faucet standards, several key differences distinguish Mexico’s certification system.

These differences are not just administrative—they also reflect environmental conditions, consumer expectations, and government priorities unique to the Mexican market.

Testing Focus and Environmental Simulation

The 96-hour salt spray test required by NOM-012-CONAGUA-2021 stands out as one of the most distinctive testing conditions.

This accelerated corrosion test is not mandatory under ASME or CSA standards, although similar optional procedures exist.

Mexico’s inclusion of this requirement reflects the country’s diverse climates—from coastal humidity to industrial pollution—where corrosion resistance is vital for product longevity.

Manufacturers who meet this test demonstrate superior plating adhesion, material quality, and finish durability, which enhances market confidence.

Certification and Regulatory Authority

In Mexico, CONAGUA (Comisión Nacional del Agua) directly oversees the plumbing product certification system.

Manufacturers must work with CONAGUA-approved laboratories, and only products bearing the official NOM mark can be legally sold or imported.

In contrast, the United States and Canada rely on independent third-party organizations such as NSF International, IAPMO R&T, CSA Group, and UL.

These groups operate under accreditation programs but are not government agencies.

The NOM certification process is therefore more centralized and government-controlled, ensuring consistent national enforcement but potentially extending lead times for approval.

Labeling and Language Requirements

Labeling rules differ significantly among the three regions:

- NOM-012-CONAGUA-2021:Product markings and documentation must be in Spanish, including the NOM certification number and manufacturer details.

- USA:Labels typically include the NSF, ASME, or WaterSense logo, with documentation in English.

- Canada:Requires bilingual labeling (English/French) and a visible CSA mark on both packaging and product.

For international exporters, multilingual labeling strategies are essential to ensure legal compliance in each market.

Flow Rate and Efficiency Tolerances

While all three regions emphasize water conservation, there are slight numerical differences in flow rate thresholds.

Application | NOM-012-CONAGUA-2021 | USA (EPA WaterSense) | Canada (CSA/WaterSense) |

Bathroom Faucets | ≤ 5.7 L/min | ≤ 5.7 L/min | ≤ 5.7 L/min |

Kitchen Faucets | ≤ 9 L/min | ≤ 8.3 L/min | ≤ 8.3 L/min |

Showers | ≤ 9.5 L/min | ≤ 9.5 L/min | ≤ 9.5 L/min |

Mexico’s slightly higher kitchen faucet limit allows for more flexibility in applications such as dishwashing, where strong water pressure is preferred.

However, EPA WaterSense in the U.S. enforces stricter tolerances to support long-term water conservation targets.

Audit and Maintenance Requirements

Under NOM-012-CONAGUA-2021, ongoing surveillance of certified products is performed by CONAGUA and the authorized testing laboratory.

Periodic inspections verify that the faucet model continues to meet all lead, flow, and corrosion parameters.

In the U.S. and Canada, audit procedures are carried out by the certifying organization (e.g., NSF, CSA, IAPMO).

Manufacturers typically undergo annual audits, during which random product samples are re-tested.

Although the approach differs, all systems aim to maintain long-term compliance and quality consistency.

Testing Environment and Standards Reference

Each standard references different testing environments and laboratory methods:

Testing Aspect | NOM-012-CONAGUA-2021 | US Standards | Canadian Standards |

Lead Testing | Mexican national method aligned with NSF 372 | NSF/ANSI 372 | NSF/ANSI 372 |

Corrosion Test | 96-hour salt spray (required) | Optional (ASME) | Optional (CSA) |

Flow Testing | Nominal pressure 0.3 MPa | 0.5 MPa typical | 0.5 MPa typical |

Pressure Endurance | 500,000 cycles | 500,000 cycles | 500,000 cycles |

Marking | NOM Logo + Lab ID | NSF/ASME logos | CSA bilingual label |

These variations influence how manufacturers prepare test samples, particularly for surface finishing and water-pressure simulations.

Adapting production to meet the strictest among these conditions helps ensure compliance in all three countries simultaneously.

Documentation and Traceability

One of the major differences lies in documentation control.

NOM-012-CONAGUA-2021 requires detailed Spanish-language technical documentation, including:

- Material composition certificates.

- Test results for lead, corrosion, and flow.

- Manufacturing batch identification.

U.S. and Canadian certification bodies, by contrast, often accept English documentation and digital traceability systems.

For companies exporting to Mexico, translating and localizing compliance reports is a crucial but often overlooked step.

Impact on Product Design

Because of Mexico’s specific environmental and language requirements, manufacturers may need to adapt certain design aspects:

- Use thicker electroplating layersto pass salt spray tests.

- Apply bilingual or Spanish-only marking plates.

- Include additional documentation in Spanishfor customs clearance.

While these changes add minor cost, they substantially increase brand credibility and allow products to meet NOM-012-CONAGUA-2021 faucet standards alongside plumbing standards USA and plumbing standards Canada.

Comparative Summary Table

Category | NOM-012-CONAGUA-2021 (Mexico) | US Plumbing Standards | Canadian Plumbing Standards |

Authority | Government agency (CONAGUA) | Private organizations (NSF, ASME, IAPMO) | CSA / Provincial enforcement |

Salt Spray Test | Required (96 hours) | Optional | Optional |

Lead Limit | ≤ 0.25% | ≤ 0.25% | ≤ 0.25% |

Flow Rate | 9 L/min | 8.3 L/min | 8.3 L/min |

Labeling | NOM mark in Spanish | NSF/ASME marks in English | CSA mark, English/French |

Certification Renewal | Periodic verification | Annual audit | Annual audit |

Focus | Corrosion & compliance control | Water efficiency & mechanical testing | Bilingual compliance & durability |

Practical Implications for Manufacturers

For manufacturers aiming to sell faucets in North America, understanding these differences is critical to avoid duplication of effort.

A strategic approach is to design faucets according to the strictest combination of requirements, ensuring simultaneous compliance in all three regions.

For example:

- Use lead-free brasscertified under NSF 372.

- Adopt flow restrictorsto meet WaterSense limits.

- Conduct 96-hour salt spray teststo meet Mexican durability standards.

By integrating these into production, a single faucet model can be certified under NOM-012-CONAGUA-2021, NSF/ASME, and CSA — maximizing export efficiency and reducing time-to-market.

Testing and Verification Procedures Across Standards

Testing is at the heart of faucet certification. Whether in Mexico, the United States, or Canada, plumbing standards all aim to verify safety, durability, and performance through measurable laboratory assessments.

However, the testing conditions, durations, and metrics differ significantly between NOM-012-CONAGUA-2021, NSF/ASME, and CSA systems.

This chapter compares the main testing methods and verification protocols, focusing on practical implications for manufacturers and importers.

Material Safety Testing

Mexico – NOM-012-CONAGUA-2021

NOM-012 requires that faucets in contact with potable water must not release lead or other toxic substances.

Lead content is measured in the wetted parts of the faucet (valve bodies, spouts, connectors), and the maximum allowable concentration is 0.25%, in line with international “lead-free” definitions.

Testing involves acid extraction and ICP (Inductively Coupled Plasma) analysis to measure metal ions. Mexican laboratories approved by CONAGUA or EMA (Entidad Mexicana de Acreditación) must perform this test.

USA – NSF/ANSI 61 & 372

The U.S. approach is nearly identical in principle but stricter in procedural validation. NSF uses a flowing water extraction test, where water runs through the faucet over multiple days to simulate real use.

Contaminant levels in collected samples must not exceed NSF/ANSI 61 limits for lead, nickel, or arsenic.

This provides dynamic, real-world assurance—something NOM-012 laboratories are beginning to integrate into their 2025-onward upgrades.

Canada – CSA / NSF Equivalence

Canada fully adopts NSF/ANSI 61 and 372 under its CSA system. The testing methods, permissible lead concentrations, and certification marks are all harmonized across North America.

Summary: All three standards confirm lead-free compliance (≤ 0.25%), but NOM-012’s ICP method and NSF’s flowing extraction test differ slightly in testing simulation.

Corrosion Resistance (Salt Spray Testing)

One of the most distinct features of NOM-012-CONAGUA-2021 is its mandatory salt spray test, which is not required under standard NSF or CSA protocols.

Mexico – NOM-012-CONAGUA-2021

- Duration: 96 hours continuous

- Environment: 5% NaCl solution at 35 °C.

- Requirement: No visible corrosion, blistering, or finish degradation on exposed surfaces.

This test ensures that faucets maintain their aesthetic finish and structural integrity in humid or coastal environments—conditions common in Mexico.

NSF / ASME

U.S. standards emphasize mechanical durability rather than corrosion resistance. While manufacturers may perform optional ASTM B117 salt spray testing, it is not a certification requirement.

CSA

CSA standards also focus on structural and mechanical endurance, though corrosion testing may be requested for commercial-grade fixtures.

Summary: NOM-012 places stronger emphasis on surface coating and plating durability, giving it an edge for tropical markets.

Mechanical and Performance Testing

Mexico – NOM-012-CONAGUA-2021

Tests include:

- Flow rate verification:Maximum flow per faucet type.

- Valve durability:200,000 open/close cycles.

- Leak tightness:Zero leakage under 1 MPa pressure.

- Handle strength:Must withstand torque stress without deformation.

ASME A112.18.1 / CSA B125.1

Covers similar parameters but includes additional evaluations:

- Thermal shock testing(temperature cycling).

- Spout rotation fatigue test.

- Flexible hose burst strength.

These are highly comprehensive and simulate long-term household use conditions.

Summary: NOM-012 and ASME/CSA are functionally equivalent in performance testing, though ASME protocols are generally broader and more detailed.

Flow Rate and Water Efficiency

All standards recognize water conservation as a crucial environmental goal.

Region | Typical Max Flow Rate | Relevant Standard | Remarks |

Mexico | 9 L/min | NOM-012-CONAGUA-2021 | Applies to bathroom and kitchen faucets |

USA | 1.5–2.2 GPM (5.7–8.3 L/min) | EPA WaterSense | Mandatory for labeled products |

Canada | 8.3 L/min | CSA + WaterSense | Follows U.S. efficiency criteria |

✅ Insight: NOM-012 aligns well with EPA WaterSense limits. Manufacturers producing dual-certified faucets can reuse designs across North America with minimal modification.

Endurance and Life-Cycle Testing

All three standards include valve endurance testing, verifying that faucets maintain seal integrity over tens or hundreds of thousands of cycles.

- NOM-012:200,000 open/close cycles.

- ASME/CSA:500,000 cycles for premium products.

Higher endurance testing in ASME/CSA ensures top performance for commercial and institutional use.

For residential markets, NOM-012 testing is fully sufficient.

Factory Audits and Ongoing Verification

U.S. and Canadian certification systems rely heavily on third-party surveillance audits to maintain certification integrity.

NSF, CSA, and IAPMO inspectors visit factories annually to ensure consistent production quality.

In Mexico, CONAGUA requires a Certificate of Conformity (CoC) renewal every two years, with laboratory retesting as needed.

This ensures periodic reassessment without excessive burden on small manufacturers.

Summary: The U.S./Canada model emphasizes continuous audits, while NOM-012 relies on periodic renewal testing—a cost-effective approach for developing markets.

Certification and Labeling Procedures

Once testing is complete, manufacturers must go through formal certification and labeling to legally sell faucets in each market.

This process not only ensures compliance but also strengthens brand trust and market access.

Mexico: NOM Certification through CONAGUA

To sell plumbing products in Mexico, manufacturers must obtain the NOM-012 Certificate of Compliance (Certificado NOM).

Steps:

- Applicationto a CONAGUA-approved laboratory.

- Sample submissionfor testing (lead, flow, corrosion).

- Audit(if required) by accredited inspection bodies.

- Certification issuanceand authorization to mark the product with the NOM-012 logo.

Labeling Requirements:

- NOM-012-CONAGUA-2021 logo.

- Manufacturer’s name or brand.

- Model number and flow rate.

- Country of origin (e.g., Hecho en China).

Failure to include these details can result in customs rejection or fines.

United States: NSF, ASME, and WaterSense Certifications

NSF/ANSI 61 & 372 Certification

Faucets that meet NSF’s lead-free and contaminant criteria may display the NSF mark or NSF/ANSI 61/372 label.

Certification is managed by NSF International or authorized equivalents like IAPMO or UL.

ASME A112.18.1 Compliance

Manufacturers typically self-declare ASME compliance but must maintain test reports and documentation for verification by inspectors or retailers.

EPA WaterSense Label

To earn the WaterSense mark, faucets must pass efficiency tests and be certified by an EPA-recognized lab.

The label often appears as a blue droplet icon, symbolizing eco-friendly performance.

✅ Combined labeling (e.g., NSF + WaterSense) enhances product credibility and visibility in U.S. retail channels.

Canada: CSA Certification

All plumbing fixtures sold in Canada must carry the CSA mark or equivalent (ULC, IAPMO).

Procedure:

- Submit samples for testing under CSA B125.1and NSF/ANSI 61/372.

- Undergo factory auditsby CSA Group inspectors.

- Receive authorization to affix the CSA certification logo.

Labeling Notes:

- CSA logo must be visible and permanent.

- Bilingual labeling (English/French) required on packaging and manuals.

- Flow rate and model number clearly indicated.

Non-compliant imports may face penalties under Canada’s Consumer Product Safety Act.

Comparative Overview of Certification Labels

Market | Certification Body | Label Example | Key Features |

Mexico | CONAGUA / EMA | NOM-012 | Lead-free, corrosion-tested, flow-regulated |

USA | NSF / EPA / ASME | NSF, WaterSense | Lead-free, water-efficient |

Canada | CSA Group | CSA | Bilingual labeling, WaterSense alignment |

Insight:

Having all three logos—NOM, NSF, and CSA—on packaging significantly boosts international trust and widens market coverage.

Cost and Time Considerations

Step | NOM-012 (Mexico) | NSF/ASME (USA) | CSA (Canada) |

Testing Duration | 3–4 weeks | 4–6 weeks | 4–6 weeks |

Certification Validity | 2 years | 1 year | 1 year |

Renewal Cost | Low | Medium | Medium-High |

Audit Frequency | Biennial | Annual | Annual |

Manufacturers exporting to all three markets should coordinate synchronized testing schedules to reduce overlap and certification cost.

Cross-Recognition and Equivalency Opportunities

While NOM-012-CONAGUA-2021, NSF/ASME, and CSA systems were developed independently, they share a remarkably similar foundation: lead-free safety, mechanical durability, and water efficiency.

This similarity opens the door to cross-recognition and mutual equivalency, making it easier for manufacturers to market compliant faucets across Mexico, the United States, and Canada.

The Concept of Mutual Recognition

In international trade, mutual recognition means that if a product meets one country’s standard, it may be accepted or partially accepted in another market without retesting.

For plumbing products, this concept is still evolving, but North America is closer to alignment than ever.

Several bilateral and regional trade frameworks support this:

- USMCA (United States–Mexico–Canada Agreement) encourages technical harmonization.

- ILAC-MRA (International Laboratory Accreditation Cooperation – Mutual Recognition Arrangement) allows laboratories accredited in one country to be recognized in another.

- EMA (Mexico), ANSI (USA), and SCC (Canada) are all ILAC-MRA members.

This means that test reports from an ILAC-accredited lab in Mexico can be recognized by NSF or CSA, reducing redundant testing for exporters.

Technical Equivalencies Between Standards

Technical Parameter | NOM-012-CONAGUA-2021 (Mexico) | NSF/ASME (USA) | CSA (Canada) | Equivalency Level |

Lead-free limit | ≤0.25% | ≤0.25% (NSF/ANSI 372) | ≤0.25% | ✅ Full |

Flow rate | 9 L/min | 5.7–8.3 L/min (WaterSense) | 8.3 L/min | ✅ Partial |

Salt spray test | 96 h mandatory | Optional | Optional | ⚠️ NOM stronger |

Mechanical endurance | 200,000 cycles | 250,000–500,000 cycles | 250,000 cycles | ✅ Functional equivalence |

Labeling | NOM mark | NSF/WaterSense | CSA bilingual | ✅ Administrative difference |

Certification validity | 2 years | 1 year | 1 year | ✅ Acceptable variation |

Interpretation:

In practice, a faucet that already complies with NSF/ASME and WaterSense can achieve NOM-012 certification with only minor additional tests — typically the salt spray and labeling verification.

Benefits of Standard Alignment

- Reduced Testing Costs:

Manufacturers no longer need to repeat entire test cycles; they can reuse verified data across jurisdictions. - Faster Market Entry:

Mutual acceptance speeds up customs clearance and registration in each country. - Unified Branding:

Having a single faucet model carrying NOM + NSF + CSA markssimplifies packaging, marketing, and after-sales service. - Sustainability and Waste Reduction:

Shared standards mean fewer prototype iterations and reduced material waste in testing.

Real-World Example: Dual-Certified Faucets

Several global brands—such as Moen, Kohler, Delta, and Faucetu OEM lines—already design faucets that comply simultaneously with NOM-012, NSF/ASME, and CSA standards.

These models are:

- Lead-free certifiedfor all markets.

- WaterSense compliant(flow ≤ 8.3 L/min).

- Corrosion-resistantunder 96-hour salt spray testing.

Such products can be exported seamlessly between Tijuana, Texas, and Toronto without major modification.

This is particularly valuable for OEM suppliers in China, who can produce one design that meets all North American standards, drastically improving production efficiency.

Toward a Unified North American Faucet Standard

Industry associations are moving toward the creation of a North American Plumbing Standard Framework, which may unify faucet testing criteria under a single umbrella by 2030.

If realized, it would:

- Integrate NOM, NSF, and CSAinto a mutually recognized structure.

- Adopt shared water efficiency benchmarks (e.g., WaterSense).

- Standardize labeling (trilingual Spanish/English/French).

This harmonization would make North America one of the easiest regions in the world for cross-border plumbing trade.

Challenges and Future Trends in Standard Harmonization

While harmonization offers clear benefits, it also presents challenges—technical, administrative, and political.

This chapter explores these challenges and outlines emerging trends shaping the future of plumbing standards in North America.

Challenges Facing Manufacturers

1. Different Testing Protocols

Even when lead limits or flow rates are the same, testing methodologies differ.

For instance, NOM-012 uses static acid extraction for metal testing, while NSF/ASME employs dynamic water flow testing.

Reconciling these methods requires further technical cooperation.

2. Labeling and Language

Manufacturers selling across Mexico, the U.S., and Canada must handle trilingual packaging and different logo usage rules.

Failure to comply can delay customs clearance or product listing.

3. Certification Renewal Costs

While NOM-012 certificates last two years, NSF and CSA require annual renewals with additional audits.

For SMEs, this can increase operational cost and administrative burden.

4. Local Enforcement Differences

Inspection intensity varies: Canada enforces product marking strictly at customs, while Mexico relies more on post-market surveillance.

Technological Trends Influencing Standards

- Smart Faucets and IoT Integration

With the rise of touchless and smart faucets, regulators are developing new performance and safety standardsfor electronic components, sensors, and battery systems.

NOM-012 revisions are expected to address these by 2026. - Sustainable Materials and Recycling

Eco-friendly materials (e.g., PEX, stainless steel, recyclable brass) are gaining attention. Future updates may include recyclability certificationalongside corrosion testing. - Digital Certification Platforms

Governments are moving toward online verification systemswhere customs and distributors can scan QR codes to confirm certification status instantly.

This digital transparency reduces counterfeit risks. - Water Efficiency Beyond Flow Rates

New standards may measure spray efficiency and flow uniformity, ensuring reduced consumption without sacrificing comfort.

The Role of Manufacturers in Shaping the Future

Forward-looking faucet manufacturers—like Faucetu—can actively participate in standard development through:

- Membership in international standard committees (ISO, ASME, or CSA).

- Collaborating with laboratoriesto align testing protocols.

- Providing feedback to CONAGUA and NOM committeesbased on real-world production experience.

By doing so, they help ensure that future updates to NOM-012-CONAGUA-2021 remain globally relevant and technically feasible.

Consumer Impact of Harmonized Standards

Harmonization benefits not only manufacturers but also consumers:

- Improved Safety:All faucets meet strict lead-free and hygiene standards.

- Better Quality:Shared mechanical endurance benchmarks lead to longer-lasting products.

- Environmental Gains:Unified water-saving standards encourage eco-friendly choices.

- Transparent Information:Consistent labeling builds consumer confidence across borders.

Strategic Recommendations for Exporters

Strategy | Description | Benefit |

Design for Compliance | Incorporate NOM + NSF + CSA parameters from the earliest design stage. | Avoid redesign costs later. |

Partner with Accredited Labs | Use ILAC-recognized labs to gain cross-recognized reports. | Reduce retesting delays. |

Standardize Components | Use common valves, aerators, and cartridges for all markets. | Simplifies inventory management. |

Invest in Certification Management | Appoint a compliance manager to track renewals and audits. | Ensures continuous market access. |

Promote Certification in Marketing | Highlight logos (NOM, NSF, CSA, WaterSense) in catalogs and websites. | Builds global trust and visibility. |

Tip for OEM Suppliers:

When negotiating with buyers, highlight that your faucet meets triple certification criteria—it’s an instant credibility boost.

The Future of NOM-012 and Its Global Relevance

Mexico’s NOM-012-CONAGUA-2021 is no longer a regional standard—it’s becoming part of a global compliance network for water safety.

As more Latin American countries adopt similar frameworks, NOM-012 could serve as a reference model for Central and South America, much like NSF/CSA standards influence the U.S. and Canada.

In the long term, international harmonization will make faucet certification faster, cheaper, and more transparent—benefiting manufacturers, distributors, and consumers alike.

Conclusion

The comparison of NOM-012-CONAGUA-2021, NSF/ASME, and CSA plumbing standards reveals a high degree of technical alignment and a shared mission: ensuring safe, durable, and efficient faucets for consumers.

While differences remain in testing methods and labeling, the path toward North American harmonization is clear.

Manufacturers who embrace multi-standard compliance today—especially through ILAC-recognized laboratories—will be best positioned to lead in tomorrow’s integrated plumbing market.

As the industry moves toward smart, sustainable, and cross-certified faucet solutions, NOM-012-CONAGUA-2021 stands as both a symbol of Mexico’s regulatory progress and a bridge connecting North America’s plumbing future.