What is NOM-012-CONAGUA-2021?

The Importance of Standards in the Faucet Industry

In the world of faucet manufacturing, product standards are the universal language of trust. Whether in Mexico, Europe, or Asia, every faucet must meet a set of technical and safety benchmarks before reaching a home, hotel, or hospital.

These benchmarks are not just about compliance — they ensure that faucets deliver clean, safe, and efficient water for years of daily use. The NOM-012-CONAGUA-2021 standard in Mexico and the European stainless steel faucet standard family in Europe share the same mission: to protect users’ health, guarantee corrosion resistance, and promote sustainable material practices.

In modern plumbing, standards define not only product quality but also brand credibility. Manufacturers that achieve recognized certifications signal their commitment to quality and public safety.

A lead-free faucet with proven corrosion resistance performs reliably under constant water exposure, ensuring durability and environmental safety. Global buyers increasingly demand documentation that proves compliance with international faucet standards, making this an essential part of today’s competitive marketplace.

From Local Regulations to Global Trust

Every market begins with local needs. In Mexico, CONAGUA (the National Water Commission) developed NOM-012-CONAGUA-2021 to regulate faucets and valves, setting strict rules for material safety and performance testing.

Across the Atlantic, European authorities established the EN 817, EN 1111, and EN 10088 series — all focused on faucet endurance, flow performance, and stainless steel material composition. Though born from different regions, both systems share the same goals: safe drinking water, efficient flow control, and materials that resist corrosion and degradation.

This alignment between NOM-012-CONAGUA-2021 and European standards allows manufacturers to design products that meet multiple certifications.

As a result, factories like Faucetu can export compliant faucets to both Mexico and the European Union, ensuring customers receive the same high-quality performance across continents. In an increasingly connected market, dual compliance is more than a technical achievement — it’s a competitive advantage that opens doors to global trade.

The Rise of Stainless Steel as a Global Benchmark

In recent decades, stainless steel has emerged as the gold standard for faucet materials worldwide. Its corrosion resistance, hygiene properties, and recyclability make it the perfect choice for modern plumbing.

Under EN 10088, stainless steel grades such as 304 and 316 are defined by their chemical composition — containing chromium and nickel that form a passive protective layer against rust and pitting. Similarly, NOM-012-CONAGUA-2021 encourages the use of durable, non-toxic metals for long-term performance and water safety.

For manufacturers, this means more than just material selection. It requires advanced processes like passivation, electropolishing, and salt spray testing to meet both European and Mexican requirements.

A corrosion resistance faucet that passes the 96-hour salt spray test under NOM-012 is likely to meet or exceed European expectations as well. Thus, stainless steel has become a shared foundation for compliance, helping bridge regional differences and unify global faucet quality.

Lead-Free Standards and Consumer Confidence

Consumer health awareness has changed the plumbing industry. Decades ago, brass faucets containing lead were common. Today, however, lead-free faucet certification is non-negotiable.

NOM-012-CONAGUA-2021 explicitly restricts lead content in contact materials to below 0.25%, mirroring the requirements in the European 4MS Common Approach and EN 15664. This global movement ensures that drinking water remains free of heavy metal contamination.

For brands like Faucetu, producing lead-free faucets is both a compliance requirement and a moral responsibility.

By combining NOM-012-CONAGUA-2021 compliance with European stainless steel standards, the company reinforces consumer confidence through transparent quality control and verified safety testing. In a world where end-users demand traceability, certification labels have become symbols of trust.

The Global Shift Toward Sustainable Water Solutions

Environmental protection and sustainability now influence faucet design more than ever. Both Mexican and European regulations emphasize reducing waste, extending product lifespan, and using recyclable materials.

Stainless steel fits this vision perfectly. It’s 100% recyclable, resistant to corrosion, and does not leach harmful chemicals into water. Meanwhile, the flow rate restrictions in both NOM-012-CONAGUA-2021 and EN 246 ensure efficient water usage without compromising user comfort.

The rise of eco-friendly faucets represents a fundamental shift in how the industry defines quality. Compliance is no longer limited to passing laboratory tests — it now includes contributing to sustainable development goals (SDGs).

This new paradigm encourages manufacturers like Faucetu to adopt green manufacturing practices, reduce emissions, and pursue dual certification to satisfy environmentally conscious markets.

The Intersection of Compliance and Innovation

Technological innovation and regulation once moved on separate tracks. Today, they are interdependent. As faucet standards evolve, they push manufacturers toward better engineering, material science, and precision machining.

Compliance with NOM-012-CONAGUA-2021 or the European stainless steel faucet standard requires advanced surface treatments, CNC precision control, and rigorous testing — all of which elevate the final product’s quality.

For example, meeting both standards involves performing salt spray tests, flow accuracy measurements, and mechanical endurance cycles.

These not only ensure compliance but also foster innovation in design and production. At Faucetu, continuous R&D investment ensures that every product not only meets but exceeds both NOM and EN requirements, achieving an international level of excellence.

The Growing Need for Harmonized Global Standards

Despite regional differences, the ultimate goal of every faucet regulation is the same: clean water, safe materials, and reliable performance. As globalization deepens, standard harmonization becomes increasingly important. Importers, suppliers, and end-users benefit when standards are comparable, reducing the complexity of international certification.

NOM-012-CONAGUA-2021 already shares many principles with European systems:

- Lead-free composition requirements

- Salt spray corrosion resistance tests

- Flow rate efficiency and pressure endurance

- Material safety and performance documentation

This alignment allows manufacturers to streamline testing, reduce costs, and maintain consistent quality worldwide. It also helps governments recognize foreign certifications more easily, paving the way for cross-border trade and technical collaboration.

Looking Ahead

As the global faucet market continues to expand, the intersection between NOM-012-CONAGUA-2021 and European stainless steel standards represents more than regulation — it represents the future of water safety and design integrity. Manufacturers that understand and integrate these frameworks will lead the industry toward a unified global quality benchmark.

Ultimately, compliance is not a cost; it’s an investment in trust, longevity, and brand reputation. For Faucetu, this alignment is not just about certification — it’s about delivering reliability, sustainability, and elegance to every home and business around the world.

What is NOM-012-CONAGUA-2021?

The Origin and Purpose of NOM-012-CONAGUA-2021

The NOM-012-CONAGUA-2021 standard is one of Mexico’s most important water regulation frameworks. Issued by the National Water Commission (CONAGUA), it defines the mandatory requirements for faucets, valves, and other water outlets to ensure safe, hygienic, and durable operation. The primary goal of this regulation is to guarantee that all faucets used in Mexican homes, commercial buildings, and public facilities meet strict health, quality, and performance criteria.

The introduction of NOM-012-CONAGUA-2021 was a direct response to growing concerns about lead contamination, corrosion, and premature faucet failure caused by inferior materials. By establishing this unified technical guideline, CONAGUA provides clarity to manufacturers and importers, ensuring that every faucet installed in Mexico contributes to clean, safe, and efficient water delivery.

For global suppliers such as Faucetu, understanding NOM-012-CONAGUA-2021 is essential to accessing Mexico’s market, as compliance certification is a legal prerequisite for distribution.

The Role of CONAGUA in National Water Regulation

CONAGUA (Comisión Nacional del Agua) is the leading Mexican authority responsible for the nation’s water management, quality control, and distribution systems. Beyond managing dams and resources, the institution also regulates how water interacts with consumer-end products such as faucets, showerheads, and valves.

By issuing NOM-012-CONAGUA-2021, CONAGUA ensures that faucets not only provide clean water but also preserve water efficiency and environmental protection. This aligns closely with Mexico’s commitment to the 2030 Sustainable Development Goals (SDGs), particularly in areas of clean water access and responsible consumption.

Every product that carries the NOM certification mark has undergone strict testing in accredited laboratories recognized by EMA (Entidad Mexicana de Acreditación), ensuring the highest levels of product credibility and safety.

Main Technical Requirements of NOM-012-CONAGUA-2021

The NOM-012-CONAGUA-2021 standard defines several critical technical requirements covering materials, performance, corrosion resistance, and water efficiency.

Key parameters include:

Parameter | Requirement / Limit | Purpose |

Lead Content | ≤ 0.25% (by weight in contact materials) | Protects human health |

Salt Spray Test Duration | ≥ 96 hours | Ensures corrosion resistance faucet performance |

Flow Rate | ≤ 9 L/min for kitchen faucets, ≤ 8 L/min for basin faucets | Promotes water efficiency |

Material Quality | Non-toxic, corrosion-resistant metal or alloy (stainless steel or lead-free brass) | Ensures durability |

Coating & Finish | Uniform, no blistering or peeling after testing | Enhances longevity and aesthetics |

Each of these criteria reflects a focus on public safety, water conservation, and environmental responsibility — values shared with the European stainless steel faucet standard framework.

Lead-Free Requirement: Protecting Human Health

Among all requirements, the lead-free faucet rule stands as one of NOM-012-CONAGUA-2021’s most significant achievements. Lead exposure through contaminated water can cause severe health issues, particularly in children and pregnant women.

To address this, the standard restricts lead content in all water-contacting materials to 0.25% or less, aligning with U.S. NSF/ANSI 372 and the European 4MS Common Approach. This alignment enables manufacturers to design a single compliant product line for multiple global markets.

Faucetu implements advanced alloying and polishing technologies to ensure each faucet meets this criterion. Using high-grade stainless steel (304 or 316), the company eliminates the risk of lead contamination entirely — creating safer, NOM-012-CONAGUA-2021 compliant faucets for every household.

Salt Spray Corrosion Test: Ensuring Durability

The salt spray test is one of the core evaluations within NOM-012-CONAGUA-2021, designed to measure a faucet’s resistance to corrosion and surface degradation. This test simulates long-term exposure to humid or saline environments, replicating real-world conditions such as coastal humidity or continuous water contact.

Under the standard, every faucet must withstand 96 hours in a controlled salt spray chamber without showing visible rust, peeling, or blistering. This ensures that products remain visually appealing and structurally strong even after years of use.

European regulations also include similar tests under EN ISO 9227, meaning that a corrosion resistance faucet that passes NOM-012 testing will typically meet European stainless steel faucet standards as well. Faucetu’s in-house lab conducts both tests side by side to verify dual compliance for export readiness.

Flow Rate and Water Efficiency Control

Water conservation has become a crucial component of modern faucet design. NOM-012-CONAGUA-2021 sets specific maximum flow rates for different product categories — typically 8–9 liters per minute, depending on the application.

These restrictions aim to reduce water waste while maintaining user comfort. Faucets are tested for consistent flow under varying water pressures (0.2–0.4 MPa) to ensure stable performance in both low- and high-pressure systems.

This principle mirrors the European EN 246 standard, which defines similar performance parameters. By adhering to both frameworks, Faucetu guarantees that every faucet operates efficiently, saving water and energy while complying with both Mexican and European environmental policies.

Coating and Surface Finish Requirements

The aesthetic and durability of a faucet depend heavily on its surface treatment. According to NOM-012-CONAGUA-2021, finishes such as chrome plating, brushed nickel, or stainless steel polishing must remain uniform and free from blistering after performance tests.

This ensures long-term shine, resistance to household cleaners, and protection against corrosion. European standards like EN 817 impose similar coating integrity tests, requiring that no visible defects appear after extended humidity exposure or abrasion cycles.

Faucetu’s stainless steel faucets are produced using electropolishing technology to create a dense, smooth oxide layer that naturally resists corrosion — reducing the need for traditional chrome plating and meeting eco-friendly manufacturing expectations.

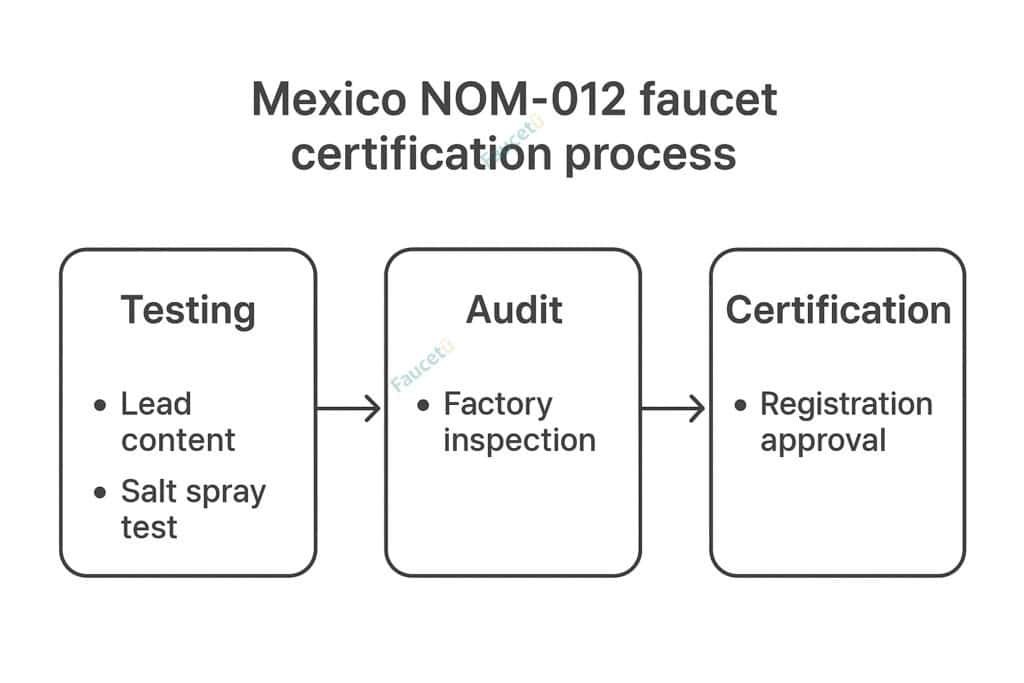

Testing, Certification, and Factory Audit Procedures

To legally sell a faucet in Mexico, manufacturers must undergo a formal certification process supervised by CONAGUA and accredited testing laboratories.

The process includes:

- Sample Submission – Representative products are sent to a certified lab.

- Laboratory Testing – Verification of lead content, flow rate, corrosion resistance, and mechanical performance.

- Document Review – Evaluation of technical specifications, drawings, and material declarations.

- Factory Audit – Inspectors verify that production aligns with certified models.

- Certification Issuance – Once all tests pass, the product receives the NOM compliance certificate and labeling authorization.

The certificate must be renewed periodically, ensuring continuous quality control. For companies exporting to both Mexico and Europe, dual certification significantly enhances brand credibility.

Faucetu, for instance, integrates its ISO 9001 quality management system into the NOM certification process to maintain consistent manufacturing and documentation practices.

How NOM-012 Benefits Manufacturers and Consumers

The enforcement of NOM-012-CONAGUA-2021 benefits all stakeholders in the plumbing industry. For manufacturers, it creates a transparent framework to design and market products that meet national expectations. For consumers, it guarantees that every certified faucet is lead-free, corrosion-resistant, and water-efficient.

By following the standard, companies like Faucetu strengthen their reputation and gain access to government projects, hotels, and infrastructure contracts that require certified faucets. For the end-user, this means cleaner water, reduced maintenance costs, and a longer-lasting product that aligns with international standards.

Alignment with Global Quality Trends

The NOM-012-CONAGUA-2021 standard is not an isolated regulation but part of a global trend toward standard harmonization. Its focus on corrosion testing, flow control, and lead-free materials closely aligns with European and North American standards. This makes compliance easier for global manufacturers and facilitates cross-border trade.

By designing faucets that meet both NOM-012 and European stainless steel standards, companies position themselves as global players capable of delivering consistent quality in any market. Faucetu’s dual-compliance products demonstrate that international cooperation in standardization benefits not only manufacturers but also the consumers who rely on safe and sustainable plumbing every day.

The European Stainless Steel Faucet Standard: Composition, Corrosion Resistance, and Durability Testing

Overview of the European Stainless Steel Standard System

In Europe, the faucet manufacturing industry is governed by a series of stainless steel material standards defined under the EN (European Norm) and ISO frameworks.

These standards ensure that faucets are safe, lead-free, and corrosion-resistant, aligning closely with the objectives of NOM-012-CONAGUA-2021 in Mexico.

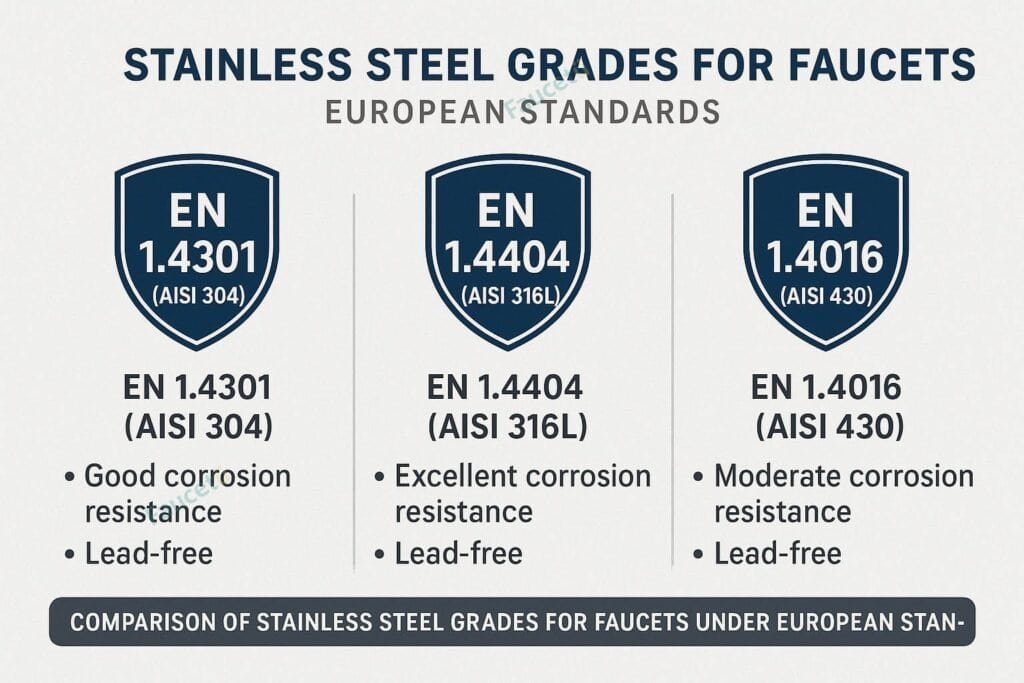

The most common stainless steel grades used in faucet production include EN 1.4301 (AISI 304) and EN 1.4404 (AISI 316L). These grades are celebrated for their durability, ease of cleaning, and resistance to pitting and rust.

While NOM-012-CONAGUA-2021 regulates performance and hygiene, the European stainless steel standard focuses primarily on material composition, metallurgical structure, and corrosion testing.

Key Material Grades Used in Faucet Manufacturing

European faucet manufacturers primarily use two stainless steel grades, each offering specific performance advantages:

- EN 1.4301 / AISI 304 Stainless Steel:

This is the most widely used stainless steel in household faucets. It contains 18% chromium and 8% nickel, which provide excellent corrosion resistance for indoor applications.

It is fully lead-free, making it suitable for drinking water systems, in accordance with the European Drinking Water Directive (DWD 2020/2184). - EN 1.4404 / AISI 316L Stainless Steel:

Often referred to as “marine-grade” stainless steel, 316L contains 2–3% molybdenum, enhancing resistance against chloride corrosion and salt exposure.

This makes it ideal for coastal regions or faucets subjected to high humidity. The 316L grade is also preferred for premium faucets exported globally, including to markets regulated by NOM-012-CONAGUA-2021. - EN 1.4016 / AISI 430 Stainless Steel:

This ferritic stainless steel contains no nickel but offers solid resistance to oxidation and scaling. While it is more affordable, it’s typically used in decorative faucet components rather than in water contact parts.

Corrosion Resistance Testing in Europe

To guarantee long-lasting performance, the European stainless steel faucet standard mandates strict corrosion tests similar to those under NOM-012-CONAGUA-2021.

These include:

- Neutral Salt Spray Test (EN ISO 9227):

Faucets are exposed to a fine salt mist for 96 to 240 hours, depending on the intended application. The test evaluates coating quality, base material stability, and potential surface pitting. - Humidity Test (EN ISO 6270-2):

This test measures how stainless steel reacts under continuous condensation. It verifies whether the faucet maintains its luster and integrity in humid bathroom or kitchen environments. - Acetic Acid Salt Spray (AASS) Test:

Used for coated or painted components, this test replicates urban pollution and acid rain exposure, ensuring that faucets remain corrosion-resistant and visually appealing.

These testing standards complement NOM-012-CONAGUA-2021’s 96-hour salt spray requirement, proving that both Mexico and Europe share a unified goal: reliable, corrosion-resistant faucets.

Mechanical Durability and Pressure Resistance

European regulations also emphasize mechanical endurance—faucets must maintain consistent performance after extensive use.

Key mechanical tests include:

- Handle Operation Test:

Faucet handles must withstand 70,000 opening and closing cycles, identical to NOM-012-CONAGUA-2021’s mechanical requirement. - Pressure and Flow Testing (EN 817):

This standard ensures the faucet operates safely under pressures up to 1,000 kPa (10 bar) without leaking or deformation. - Thermal Shock Resistance:

Faucets are subjected to rapid temperature changes between 5°C and 90°C to ensure that internal components (cartridges, seals, aerators) can handle daily thermal stress.

These tests collectively guarantee long-term faucet reliability, whether the product is installed in European households or exported globally under multi-market certifications.

Surface Finish and Aesthetic Durability

Beyond mechanical endurance, Europe’s stainless steel faucet standard values visual and tactile quality.

Manufacturers must ensure a uniform surface finish, free from visible defects such as scratches, pores, or welding marks.

Common finishes include:

- Brushed Stainless Steel (Satin Finish): Elegant, fingerprint-resistant, and ideal for modern kitchens.

- Polished Finish (Mirror Gloss): Used for luxury bathroom faucets with a reflective surface.

- PVD Coating: Provides color variations (black, gold, gunmetal) with excellent adhesion tested under ISO 2819.

These finishing standards align with consumer preferences for aesthetics and hygiene, echoing NOM-012-CONAGUA-2021’s focus on product quality and durability.

European Certification Marks and Their Role

In Europe, compliance with stainless steel standards and faucet performance is demonstrated through certifications such as:

- CE Marking (Conformité Européenne):

Indicates the faucet meets EU safety, health, and environmental protection standards. - ACS (France) & WRAS (UK):

Confirm faucet materials are safe for potable water contact. - EN 817 / EN 200 Compliance:

Ensures consistent water flow, sealing performance, and mechanical stability. - Together, these marks function similarly to NOM-012-CONAGUA-2021 certification, proving product compliance and instilling consumer trust.

Shared Goals Between NOM-012-CONAGUA-2021 and European Standards

Both regulatory frameworks serve a unified mission: to promote safe, corrosion-resistant, and eco-friendly faucets.

While NOM-012-CONAGUA-2021 focuses on national compliance within Mexico, the European stainless steel standard represents a global benchmark for material integrity.

For manufacturers like Faucetu, adhering to both systems means producing faucets that satisfy international expectations for safety, durability, and sustainability—opening doors to worldwide markets.

Comparative Analysis: NOM-012-CONAGUA-2021 vs European Stainless Steel Standards

Introduction to the Comparative Framework

The global faucet industry increasingly depends on harmonized standards that ensure safety, sustainability, and cross-market reliability.

While NOM-012-CONAGUA-2021 is specific to Mexico, its core values mirror those of European stainless steel faucet standards, emphasizing lead-free composition, corrosion resistance, and mechanical endurance.

By comparing the two, we can identify technical intersections and philosophical similarities—a vital insight for global manufacturers such as Faucetu, who design faucets that comply with both sets of requirements.

Comparison Table: NOM-012-CONAGUA-2021 vs European Standards

Aspect | NOM-012-CONAGUA-2021 (Mexico) | European Stainless Steel Standards (EN / ISO / CE) | Key Observation |

Regulatory Authority | CONAGUA (National Water Commission of Mexico) | European Committee for Standardization (CEN), European Commission | Both institutions promote safe water use and product compliance. |

Material Composition | Lead content ≤ 0.25%, corrosion-resistant alloys | Stainless steel grades 304, 316L, 430 – lead-free and durable | Both require non-toxic materials safe for potable water. |

Corrosion Testing | 96-hour neutral salt spray test | EN ISO 9227 – 96 to 240-hour salt spray test | Testing procedures and objectives are almost identical. |

Mechanical Endurance | 70,000 operation cycles | EN 817 – 70,000 to 100,000 cycles | Equivalent durability benchmarks for faucet longevity. |

Flow Rate Regulation | ≤9 L/min for kitchen faucets | EN 200 – regulated flow to optimize water conservation | Both integrate water efficiency principles. |

Thermal Shock Resistance | Not explicitly specified | Required (EN 817: 5°C–90°C cycle) | Europe has additional thermal testing. |

Certification Mark | NOM-012-CONAGUA-2021 compliance label | CE, WRAS, ACS | Different marks, same purpose: user confidence and traceability. |

Environmental Goal | Prevent water contamination, promote sustainable design | Support EU Green Deal, energy and water-saving directives | Shared environmental responsibility across continents. |

Shared Commitment to Lead-Free Safety

Both standards are rooted in public health protection.

The lead-free faucet requirement in NOM-012-CONAGUA-2021 (≤0.25% lead) aligns precisely with the European Drinking Water Directive (DWD 2020/2184), which also mandates the use of non-toxic materials in plumbing systems.

This alignment enables manufacturers like Faucetu to streamline material selection, using certified stainless steels such as AISI 304 and 316L that already meet both Mexican and European safety limits.

Such consistency reduces production complexity and strengthens international trust in product safety.

Corrosion Resistance: A Global Benchmark

Corrosion is a major cause of faucet degradation, particularly in humid or coastal regions.

Both NOM-012-CONAGUA-2021 and European standards use the neutral salt spray test (ASTM B117 / EN ISO 9227) to simulate long-term exposure to moisture and salt.

In Mexico, the requirement is 96 hours minimum—sufficient to verify anti-corrosion coating quality.

In Europe, testing may extend up to 240 hours for high-grade finishes such as PVD or marine-grade stainless steel.

This demonstrates a shared global commitment to corrosion resistance, though Europe’s test range reflects its broader environmental diversity and higher exposure standards.

Mechanical Endurance and Functionality

A faucet’s lifespan depends on its ability to withstand repetitive use.

Both NOM-012-CONAGUA-2021 and EN 817 require at least 70,000 operation cycles, ensuring that faucets remain leak-free, smooth-operating, and structurally sound.

European standards, however, often expand testing to 100,000 cycles for commercial or industrial faucets, pushing manufacturers to design even more robust internal cartridges and valve assemblies.

This shared endurance goal ensures that consumers in Mexico and Europe receive equally durable products, promoting global reliability across markets.

Water Efficiency and Sustainability Alignment

Water conservation is a critical part of modern faucet design.

NOM-012-CONAGUA-2021 sets strict flow limits—9 L/min for kitchens and 8 L/min for basins—encouraging sustainable consumption.

In Europe, EN 200 and EU EcoDesign directives serve a similar role, requiring efficient flow regulators and aerators to minimize water waste.

Both standards encourage faucet makers to integrate eco-friendly technologies like aerated streams and thermostatic mixing valves.

For Faucetu, this creates opportunities to highlight water-saving innovation while maintaining compliance on both continents.

Certification, Traceability, and Market Transparency

Certification marks are the visual language of compliance.

In Mexico, the NOM-012-CONAGUA-2021 label confirms that the faucet meets national testing standards and has passed laboratory verification.

In Europe, the CE marking serves the same purpose—ensuring that the faucet conforms to essential safety and health directives before entering the market.

Both systems also require traceable documentation, enabling authorities and consumers to track product origin and test results.

This transparency builds brand credibility and encourages ethical manufacturing practices.

Environmental Responsibility and Green Design Philosophy

A defining similarity between NOM-012-CONAGUA-2021 and European standards lies in their eco-conscious philosophy.

Both promote lead-free materials, energy-efficient water flow, and long-lasting design—factors that minimize environmental impact throughout the product lifecycle.

European regulations, through initiatives like the EU Green Deal, take a broader sustainability approach by encouraging recyclable materials and carbon footprint reduction.

Meanwhile, NOM-012-CONAGUA-2021 focuses on safe water delivery and environmental protection within Mexico’s context, creating complementary goals for international collaboration.

Challenges in Dual Compliance

While the two systems align philosophically, manufacturers seeking dual compliance face certain challenges:

Documentation Complexity: Different formats for test reports and conformity declarations.

Testing Costs: Dual certification may require additional lab testing and administrative steps.

Regional Labeling Requirements: Packaging and product markings must be adapted per market.

Despite these differences, the overlap in testing criteria (especially salt spray and mechanical tests) simplifies the engineering process for global suppliers such as Faucetu, who design faucets optimized for worldwide certification compatibility.

Benefits of Alignment for Global Trade

The convergence of NOM-012-CONAGUA-2021 and European stainless steel standards benefits the global faucet industry in several ways:

Easier cross-border trade and export opportunities.

Reduced duplication of testing procedures.

Increased consumer confidence in certified products.

Simplified OEM manufacturing for companies supplying multiple continents.

For international brands like Faucetu, this alignment supports global expansion, enabling the same faucet model to meet Mexican, European, and North American market standards with minimal modification.

How Manufacturers Can Ensure Compliance with NOM-012-CONAGUA-2021

For faucet manufacturers, understanding and implementing NOM-012-CONAGUA-2021 is not just about meeting regulatory demands — it’s about building long-term credibility and market competitiveness in Mexico. Ensuring compliance requires a systematic approach, from material selection to production and final quality inspection.

Step 1: Understanding Technical Requirements

Before production begins, manufacturers must fully understand all sections of NOM-012-CONAGUA-2021, including:

- The acceptable lead content levels (less than 0.25%).

- Requirements for salt spray resistance (minimum 96 hours without corrosion).

- Flow rate limits, ensuring water conservation and performance balance.

- Marking and labeling requirements, including product information and certification numbers.

Creating an internal compliance manual based on these standards helps guide the engineering and quality teams.

Step 2: Material Sourcing and Testing

Raw materials play a crucial role in faucet safety and performance. Manufacturers should:

- Source lead-free brass or stainless steel certified for drinking water use.

- Request material composition certificates from suppliers.

- Conduct independent lab tests to confirm compliance with heavy metal and corrosion standards.

For example, Faucetu uses certified lead-free brass alloys to guarantee both health safety and long-term reliability.

Step 3: Production Process Control

Implementing process control ensures consistency:

- Use automated CNC machining for precision.

- Apply multi-layer electroplating for enhanced corrosion resistance.

- Monitor plating thickness and adhesion regularly through salt spray simulation.

- Maintain traceability records for each production batch.

Step 4: Laboratory Testing

Testing is a mandatory part of compliance. Manufacturers should maintain an internal or third-party certified laboratory capable of performing:

- Salt spray tests according to ASTM B117.

- Flow rate testing under standard pressure (0.3–0.6 MPa).

- Toxicity and heavy metal leaching tests.

- Durability testing (handle operation cycles).

Lab photos showing engineers performing these tests can serve as proof of capability and commitment to quality.

Step 5: Certification and Documentation

Once all requirements are met, the product must undergo official certification through a recognized body accredited by CONAGUA. Documentation includes:

- Test reports from approved labs.

- Technical drawings and product descriptions.

- Quality management system evidence (ISO 9001 or equivalent).

- Labeling and marking proof.

This process ensures that the faucet receives a valid NOM certification number before being distributed in Mexico.

Common Mistakes Manufacturers Should Avoid

Despite good intentions, many manufacturers fail certification due to preventable errors. Recognizing these pitfalls early can save time and money.

1. Ignoring Lead Compliance

Some manufacturers continue using old brass formulas containing high lead levels. Even if performance is good, these materials automatically fail NOM-012 testing. Always verify alloy composition.

2. Using Inferior Electroplating

Insufficient plating layers or poor adhesion can cause early corrosion during the 96-hour salt spray test. The result: immediate rejection. Investing in nickel-chromium double plating or PVD coating can improve results dramatically.

3. Lack of Pre-testing Before Submission

Sending products directly to certification labs without internal pre-tests often leads to failure. Always conduct internal tests first to simulate official procedures.

4. Incomplete Documentation

CONAGUA certification requires complete documentation — missing flow test data, unmarked product drawings, or unclear labeling can delay approval.

5. Assuming One Model Covers All

Each faucet model must be certified individually or under a defined family of products. Changing dimensions, flow restrictors, or materials may require a separate test.

Benefits of NOM-012 Compliance for Manufacturers

Becoming NOM-012 compliant unlocks numerous strategic advantages for faucet producers.

1. Legal Market Access

Compliance grants manufacturers full access to the Mexican plumbing market, including government, hotel, and public projects that require certified products.

2. Brand Credibility

Displaying the NOM certification mark enhances brand trust. Distributors and retailers prefer certified suppliers, reducing negotiation barriers.

3. Competitive Differentiation

Many low-cost competitors skip compliance, limiting their reach. By contrast, certified manufacturers like Faucetu stand out as reliable, professional partners.

4. Long-term Cost Savings

Although testing adds upfront costs, compliant designs often use higher-quality materials, leading to fewer warranty claims and customer complaints.

5. Global Market Alignment

NOM-012 aligns with other international standards (such as NSF/ANSI 61 and ISO 9227), helping manufacturers expand into North America and beyond with minimal modification.

How Consumers Can Identify Certified Faucets

For everyday consumers, distinguishing compliant faucets ensures health safety and performance.

1. Look for the NOM Mark

Certified faucets display the NOM logo followed by a certification number, typically engraved or printed on packaging or the product body.

2. Request Certification Documents

Retailers should provide a certificate of compliance or lab test summary upon request. This confirms the faucet has passed all tests under NOM-012.

3. Check Seller Reputation

Authorized distributors or factory outlets are more likely to sell genuine certified products. Always verify supplier credentials.

4. Consider Long-term Value

Although certified faucets may cost slightly more, they offer guaranteed safety and durability — preventing corrosion, leakage, and contamination issues.

Future Trends in Mexican Faucet Regulation

NOM-012-CONAGUA-2021 represents just one step in Mexico’s broader water safety strategy. The next few years may see further advancements.

1. Integration with Sustainability Goals

Future revisions may introduce water efficiency ratings and recycled material usage targets, encouraging eco-friendly manufacturing.

2. Smart Faucet Technology

As Mexico adopts smart home trends, upcoming standards could include testing protocols for sensor faucets and electronic flow control systems.

3. Stricter Enforcement

CONAGUA and PROFECO (consumer protection agency) are increasing market inspections, meaning unapproved products risk being withdrawn or fined.

4. Cross-Border Harmonization

Mexico may align NOM-012 more closely with U.S. and Canadian standards, simplifying trade for certified exporters.

Case Study: Faucetu’s Compliance Success

Faucetu, as a professional faucet manufacturer and exporter to Latin America, has fully embraced the NOM-012-CONAGUA-2021 framework.

Key Achievements:

- Developed a lead-free brass formulatailored for the Mexican market.

- Conducted in-house salt spray testsexceeding 120 hours, surpassing the required standard.

- Ensured each product model carries proper flow restrictorsmeeting Mexican efficiency requirements.

- Provided full documentation packagesfor distributors to simplify import customs procedures.

Customer Benefits:

- Distributors receive pre-certified faucets, eliminating regulatory risk.

- Installers enjoy easier compliance verification during construction audits.

- End-users gain confidence in water quality and product longevity.

Conclusion: Why NOM-012 Compliance Matters for Everyone

NOM-012-CONAGUA-2021 is not merely a technical standard — it represents a commitment to public health, environmental sustainability, and product reliability.

For manufacturers, it’s a roadmap to credibility and market growth. For consumers, it’s a safeguard against harmful materials and premature faucet failure. For the Mexican government, it’s a framework ensuring cleaner, safer water for millions.

By choosing certified faucets, everyone — from builders to homeowners — contributes to a safer and more sustainable future.

The Technical Backbone of NOM-012-CONAGUA-2021 Compliance

To understand NOM-012-CONAGUA-2021 at a deeper level, it’s important to break down its technical foundation. The standard was not created randomly — it’s built on years of engineering research, safety studies, and international alignment with NSF, ISO, and EPA standards.

Lead-Free Material Science

Lead has long been a concern in plumbing products. Under NOM-012-CONAGUA-2021:

- Maximum lead contentin any wetted surface must not exceed 25% by weight.

- Brass alloysused must be certified as “lead-free” and accompanied by a material composition report.

- Electroplated coatingscannot contain heavy metals like cadmium or nickel beyond safe limits.

Manufacturers often switch to DZR brass (Dezincification Resistant) or 316 stainless steel to meet these requirements. These materials resist corrosion and maintain water purity even under high temperatures and pressure.

Corrosion Resistance through Salt Spray Testing

One of the defining tests under NOM-012-CONAGUA-2021 is the 96-hour salt spray test (based on ASTM B117).

This test evaluates a faucet’s ability to withstand aggressive environmental conditions without peeling, rusting, or discoloration.

The Process:

- The faucet is cleaned and dried before testing.

- It’s placed inside a sealed salt spray chamber.

- The chamber sprays a fine mist of 5% NaCl (salt solution)at 35°C.

- After 96 hours, the product is inspected for corrosion spots, blistering, or coating failure.

Passing this test ensures that the faucet can survive coastal humidity, cleaning chemicals, and years of daily use.

Flow Rate and Water Efficiency Standards

Water scarcity is a key issue in Mexico. To align with national sustainability goals, NOM-012-CONAGUA-2021 limits the maximum flow rates for different faucet types:

- Basin faucets: ≤ 5.6 L/min

- Kitchen faucets: ≤ 8.3 L/min

- Showerheads: ≤ 9.5 L/min

Manufacturers achieve this through flow restrictors, aerators, and pressure-compensating valves that balance comfort and conservation.

Practical Testing Example: Salt Spray Performance Comparison

To illustrate how compliance impacts product quality, let’s analyze a comparison between non-compliant and NOM-012-compliant faucets in a salt spray environment.

Faucet Type | Material | Plating Type | Salt Spray Duration | Result |

Standard low-cost faucet | Zinc alloy | Thin chrome | 48 hours | Corrosion, blistering |

NOM-012-compliant faucet | Lead-free brass | Nickel-chrome double layer | 96 hours | No corrosion, smooth finish |

Premium PVD faucet | Stainless steel | Physical vapor deposition | 120 hours | No visible change |

This comparison clearly demonstrates that compliance directly translates into long-term durability and better user satisfaction.

The Role of Accredited Laboratories

Certification under NOM-012-CONAGUA-2021 can only be issued by authorized laboratories accredited by Entidad Mexicana de Acreditación (EMA) or other recognized institutions.

Why Accredited Labs Matter

They ensure neutrality and reliability of test results.

Their procedures follow ISO/IEC 17025 guidelines for testing and calibration.

Their reports are directly accepted by CONAGUA for certification issuance.

Testing Capabilities Include:

- Salt spray corrosion resistance.

- Flow rate and pressure endurance tests.

- Heavy metal leaching analysis.

- Mechanical durability (valve life cycles).

How Distributors Benefit from Selling Certified Faucets

For wholesalers and importers in Mexico, offering NOM-012-certified faucets is not just a legal requirement — it’s a competitive advantage.

Legal Protection

Distributors selling uncertified faucets risk fines, confiscation, or brand damage. With certification, they enjoy peace of mind and smooth customs clearance.

Easier Market Penetration

Certified faucets can be listed in government tenders, hotels, and public housing projects, which require NOM-validated products.

Marketing Advantage

Displaying certification badges and test results builds customer trust. Many e-commerce platforms now include NOM-compliance filters.

Reduced Return Rates

High-quality, corrosion-resistant products lower post-sale issues and warranty claims.

Integrating NOM-012 Compliance into OEM/ODM Manufacturing

For global faucet brands sourcing from China, compliance starts at the OEM partner level.

Key Steps for OEM Collaboration

- Define NOM requirementsin the initial design phase.

- Select compliant raw materialsand maintain traceability.

- Conduct pre-certification testingin local or third-party labs.

Prepare full documentation(drawings, BOMs, test data).

Benefits for OEM Buyers

- Ready-to-market faucets for Mexico.

- Lower risk of customs delays.

- Reduced certification cost and time.

Faucetu’s Commitment to Global Quality

As a leading faucet manufacturer, Faucetu embraces both the Mexican NOM-012-CONAGUA-2021 and European stainless steel faucet standards as guiding pillars for production. The company’s integrated quality control system monitors each stage — from material sourcing to final inspection. Every faucet undergoes a 96-hour salt spray test, flow verification, and lead-free compliance inspection.

By achieving dual-standard certification, Faucetu ensures that its products meet the expectations of distributors, architects, and end users across Latin America and Europe. This dedication to compliance and excellence underscores the company’s belief that quality knows no borders.